Companies are under pressure to reduce costs while maintaining efficiency. One key area often overlooked is pallet management. Traditional wooden pallets, though ubiquitous, present a range of challenges that drive up costs—whether through weight, wear and tear, or inefficiency in backhaul loads.

Enter BLOCKPal, a cutting-edge composite pallet that offers unparalleled strength, durability, and logistical efficiency. More than just a pallet, BLOCKPal incorporates autonomous IoT sensor technology, making it a revolutionary tool in modern freight management. Here’s how switching to BLOCKPal can help your company cut freight costs.

Strength and Durability: The Key to Reducing Transportation and Handling Costs

One of the standout features of BLOCKPal is its incredible strength. With an edge rack capacity of 6,500 lbs., it can hold more than double the weight of traditional pallets. This strength translates directly into cost savings. Heavier loads on fewer pallets mean fewer trips and less time spent handling products. The composite material also ensures the pallet maintains its structural integrity under heavy loads, meeting ISO 8611 standards. In addition, the bottom boards fail first, offering the top deck protection from damage—a key component to transporting high-value goods.

Durability is another major cost-saving factor. BLOCKPal has a lifespan of 150+ uses, significantly longer than wooden pallets. This means fewer pallets are purchased and replaced over time, reducing direct costs and downtime for restocking pallets.

Optimized for Freight Efficiency: Smaller, Lighter, and Smarter

A portion of freight costs comes down to how many pallets you can fit in a truck, and the total weight being transported. BLOCKPal offers substantial advantages in both areas.

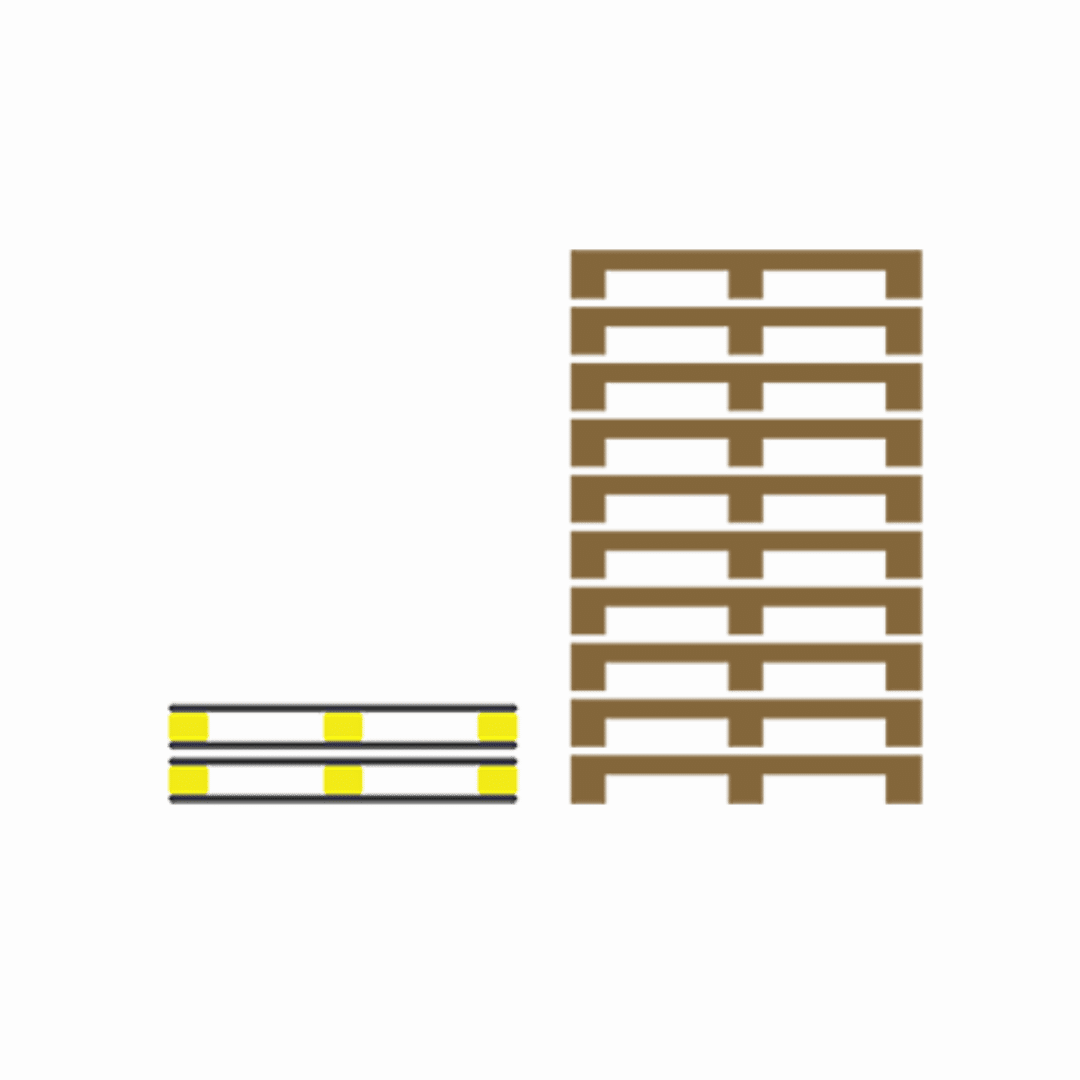

Compared to traditional pallets, BLOCKPal is 26% lighter and has a 0.67” lower profile, allowing more pallets to fit in each truckload. For instance, with BLOCKPal, you can fit up to 17% more pallets per backhaul truckload—630 pallets versus 540. The lighter weight also reduces wear and tear on handling equipment, further decreasing operational costs.

Additionally, BLOCKPal is equipped with RM2 ELIoT® technology, a built-in IoT sensor system that autonomously tracks the location and condition of each pallet. This feature eliminates additional hardware or IT infrastructure, giving companies real-time visibility into their pallets’ movements and conditions. This not only helps minimize losses and theft but also optimizes inventory management. You save on pallet accounting and the inefficiencies from lost or damaged pallets.

Environmental Friendliness: A Sustainable Freight Solution

In today’s eco-conscious world, sustainability is no longer just a buzzword—it’s a business imperative. BLOCKPal’s composite material requires no toxic or carcinogenic additives to meet fire safety regulations, and it is naturally fire-resistant, meeting the stringent FM4996 certification for fire safety. More importantly, each pallet’s lifespan allows for over 150 uses, reducing the number of pallets required to make the same number of trips.

This longevity results in a 21% lower global warming potential and a 50% reduction in energy demand compared to traditional pallets. Fewer resources are used in both the production and transportation of pallets, which directly translates into cost savings.

Consistency and Quality: No Surprises in Freight Logistics

When dealing with tight logistics schedules, unexpected issues like broken pallets or inconsistent sizes can cause costly delays. BLOCKPal solves these problems with its high-quality construction and rigid material. The maximum allowed dimensional deviation is just 0.025 inches, meaning each pallet is manufactured to precise specifications. The consistent quality means they stack better, fit uniformly in trucks, and eliminate the headaches caused by warped or misaligned pallets.

Conclusion: BLOCKPal is More Than a Pallet—It’s a Freight Optimization Tool

In a world where every dollar counts, reducing freight and handling costs can significantly impact a company’s bottom line. BLOCKPal cuts costs by being stronger, lighter, and more durable than traditional pallets, but it also optimizes freight loads and reduces environmental impact. The bonus of the RM2 ELIoT® sensor technology makes it a modern logistics tool, streamlining operations through real-time data without additional IT investments.

Whether you’re looking to cut costs in the cold chain, reduce backhaul inefficiencies, or make a more sustainable choice, BLOCKPal is the solution that pays for itself over time. So why stick with outdated wooden pallets when the future of freight optimization is here?