In companies’ ongoing efforts to reduce the environmental impact of their operations, the supply chains of the products they sell are under increasing scrutiny, and rightfully so. The world has awoken to the fact that the sustainability of products themselves—their ingredients, production, and packaging —is only one small part of the whole of the impact. The systems, materials, and transportation necessary to bring products from producer to consumer weigh heavily on our environment, accounting for up to 90% of a company’s total environmental impact. Those who manage supply chain and logistics must think as critically about the choices they make as their counterparts in product and packaging functions, or pose a significant risk to the economic viability of their companies.

Given the attention paid to supply chain sustainability, it’s no wonder every pooled pallet supplier in every country around the world is now asserting the environmental superiority of its products and services. The result is a confusing web of claims with seemingly no standardized means of comparison or validation. From the pallet user perspective, however, two categories of environmental impact have emerged as areas of greatest concern and focus: waste reduction and CO2 emissions (or Global Warming Potential). Here, we compare the impacts of three common types of pooled pallets: wood, plastic, and fiberglass composite on these two critical impact categories.

Source Material and Solid Waste Reduction

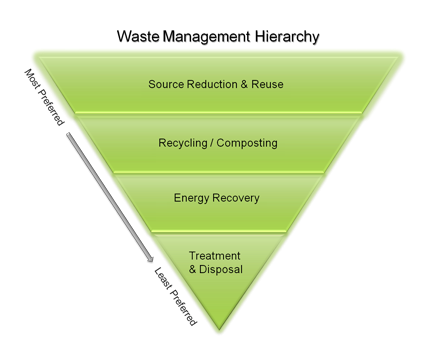

The U.S. Environmental Protection Agency (EPA) provides clear, well-established guidelines for supply chain managers to use when evaluating the solid waste impact of pallet options: the EPA Waste Management Hierarchy. In this simple hierarchy, Source Reduction and Reuse are the most preferred options, so it would follow that reusable pooled pallets would be the most preferred type of pallet, and this is certainly the case. But all reusable pallets are not created equal: reusable pallets made of different materials have vastly different useful lifespans, and therefore vastly different waste reduction benefits.

According to a peer-reviewed Life Cycle Analysis (LCA) conducted on behalf of global wood pallet pooler CHEP, a pooled wood pallet enjoys an average of 30 trips (or cycles or uses) before the end of its life cycle. A competing LCA conducted on behalf of plastic pallet pooler iGPS assumed this number to be just 15, while claiming plastic pallets enjoy up to 100 trips before end of life (a claim which was deemed highly doubtful by many in the pallet industry).

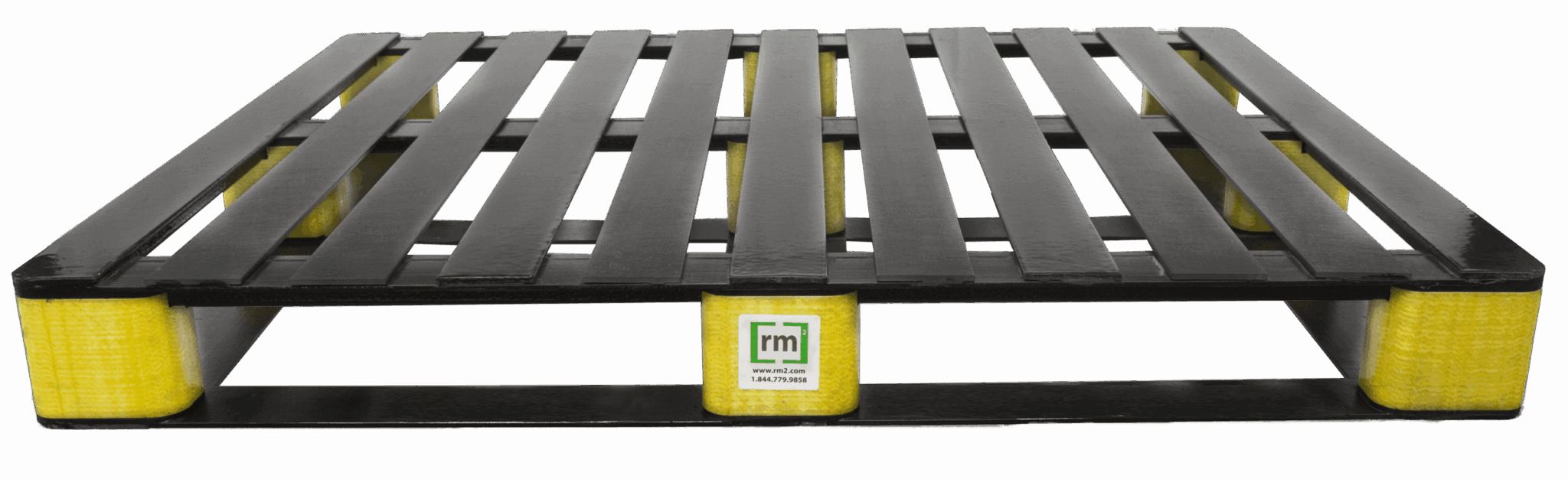

Even if we (generously) assume wood and plastic pallets will last 30 and 100 trips, respectively, neither can compete with the durability and useful longevity of fiberglass composite pallets. An ASTM D1185-compliant pallet design study conducted by the Virginia Tech Center for Packaging and Unit Load Design on behalf of global composite pallet pooler RM21 determined the company’s BLOCKPal pallets have a useful life of more than 150 trips—more than 500% longer than the best-case assumptions for pooled wood pallets and over 50% longer than pooled plastic pallets. The durability of the fiberglass composite material is not the only advantage BLOCKPal pallets have over competing pallets. Each BLOCKpal pallet features RM2 ELIoT®, an embedded pallet tracking, temperature, vibration, and accelerometer sensor device that captures the location, condition, and movement of products and assets in real time. IoT sensor data are transmitted to the cloud via the LTE-M network, making the pallet’s location and condition both indoors and in transit visible without requiring any additional hardware or IT development.

The accuracy and real-time tracking of BLOCKPal pallets minimizes loss and theft down to just 0.3% versus an average of 2% for other pooled pallets. Tracking ensures that any deviation from location or temperature is immediately signaled to facilitate on-time delivery without product spoilage. Finally, RM2’s BLOCKPal pallets are composed of just 55 pounds of material, 25% lower than the average 75 pounds of material in a pooled wood pallet, reducing the amount of source material needed for each new pallet.

CO2, Greenhouse Gas Emissions, and Global Warming Potential (GWP)

The CO2 impact of pallets, as with most reusable assets, is driven almost entirely by transportation, both of product-loaded pallets on their way from producer to retailer and of empty pallets on their way either to the producer for use or back from the retailer (or other end user) to the pallet pooler’s depot. Therefore, the pallet that offers the greatest transport efficiency, either by weight or size, will result in lower CO2 emissions and GWP. Here, the fiberglass composite RM2 BLOCKPal pallet has two advantages. First, as previously noted, BLOCKPal weighs 26% less than wood block pallets. Second, BLOCKPal’s low-profile 5.0″ height versus 5.67″ for other block pallets allows 90 more BLOCKpal pallets per backhaul truckload, reducing transportation by 17%. The connection between lower profile and lighter weight are borne out in research. An LCA, conducted by Pure Strategies according to ISO 14040/14044 standards on behalf of RM2, compared the environmental impacts of RM2’s BLOCKPal pallets with those of historically used pooled wood pallets.

Here, the fiberglass composite RM2 BLOCKPal pallet has two advantages. First, as previously noted, BLOCKPal weighs 26% less than wood block pallets. Second, BLOCKPal’s low-profile 5.0″ height versus 5.67″ for other block pallets allows 90 more BLOCKpal pallets per backhaul truckload, reducing transportation by 17%. The connection between lower profile and lighter weight are borne out in research. An LCA, conducted by Pure Strategies according to ISO 14040/14044 standards on behalf of RM2, compared the environmental impacts of RM2’s BLOCKPal pallets with those of historically used pooled wood pallets.

The study confirmed that only 899 BLOCKPal pallets are required for 100,000 one-way trips. By comparison, five times as many wooden pallets—4,400—would be required to make the same number of one-way trips. The study also determined pallet weight as the key driver of overall life cycle potential impact because it is a factor that drives impacts across the life of the pallet including the use and material production phases. Results showed that, compared with pooled wood pallets, the RM2 BLOCKPal pallet produced 21% lower GWP for the same number of trips, a significant savings.

Conclusion: material durability, real-time asset tracking and design drive pallet sustainability

After evaluating the arguments of various pallet poolers and their dueling LCAs, three themes emerge as most impactful in driving tangible results in the critical categories of solid waste and CO2 reduction:

- Pallet material durability

- Accurate and real-time tracking

- Pallet design

Pallets that perform the best in each of these three themes help lower waste and reduce GWP, the two areas of greatest concern for supply chains around the world. RM2’s BLOCKPal, by nature of its lightweight, low-profile, and highly durable fiberglass composite construction and design and embedded real-time IoT tracking device, offers significant environmental savings over both wood and plastic pallets.

Pallets that perform the best in each of these three themes help lower waste and reduce GWP, the two areas of greatest concern for supply chains around the world. RM2’s BLOCKPal, by nature of its lightweight, low-profile, and highly durable fiberglass composite construction and design and embedded real-time IoT tracking device, offers significant environmental savings over both wood and plastic pallets.

For more information on RM2’s BLOCKPal pallets and RM2 ELIoT IoT technology, contact us.

- Virginia Tech Center for Packaging and Unit Load Design Pallet Design Evaluation for RM2, Test Report-No: 2013-0049, 2014-0007, 2014-0016