In the fast-paced world of modern supply chains an unsung hero is working behind the scenes: the pallet. These platforms bear the weight of industries, enabling the seamless movement of goods from one point to another. But beyond their structural integrity and logistical significance lies a crucial factor that goes unnoticed: cleanliness. Clean pallets are the guardians of product safety, quality assurance, and operational efficiency.

Product Safety and Quality Assurance

Clean pallets contribute to the maintenance, safety, and quality of the goods transported. A dirty or contaminated pallet can introduce foreign materials, such as dust, debris, bacteria, or pests, which may compromise the integrity of the products. For industries like food, pharmaceuticals, and healthcare, where product safety is paramount, clean pallets are essential to ensure that the goods remain untainted throughout the supply chain. By utilizing clean pallets, businesses can maintain the freshness, purity, and overall quality of products, safeguarding their reputation and customer satisfaction.

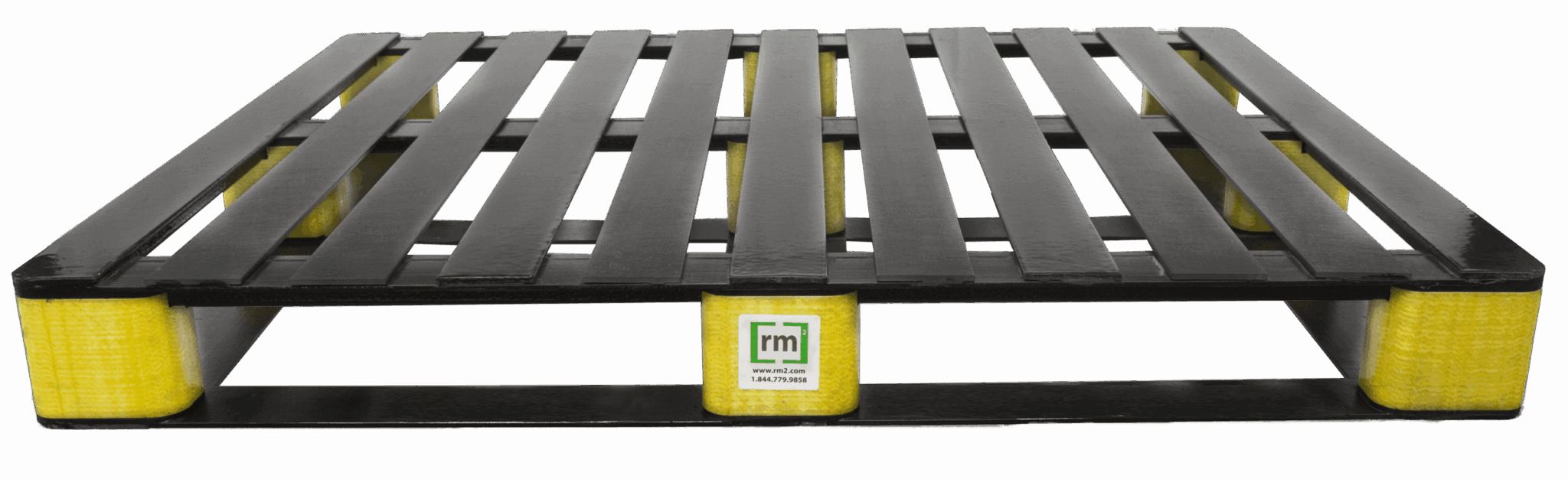

The increase in safety concerns as well as the ongoing wood pallet shortage is leaving supply chains and warehouses scrambling to find a substitute. Plastic and fiberglass composite pallets (like RM2’s BLOCKPal) are increasingly becoming that go-to replacement. Let’s look at how these two options stack up on critical issues of environmental impact, durability, and safety.

Plastic Pallets

An oil-based product, the production of plastic pallets has a significant environmental impact. These pallets do have a longer shelf life than wood at 50 uses but lack the strength and durability to sustain heavy weight or tough cold chain environments, often becoming brittle or cracking in extreme temperatures. Due to the flammability of plastic, the pallets are treated with toxic chemical flame retardants to meet fire safety regulations, creating a limitation for some uses. Plastic does offer a lighter weight than wood, helping to keep fuel costs down. However, the lack of repairability leaves the plastic pallets to be ground up and recycled at the end of their useful life.

As supply chain managers make the shift to a wood alternative, they are also looking for increased visibility into their supply chain logistics – seeking out pallet options that offer traceability. Due to economic viability, plastic pallets remain limited to geo-tracking devices that are restricted in their data-sharing capabilities.

Regulatory Compliance

Many industries operate under stringent regulations and standards to guarantee consumer safety. Clean pallets play a vital role in meeting these regulatory requirements. Regulatory agenciesset guidelines on cleanliness, hygiene, and sanitization practices to minimize the risk of contamination and maintain the integrity of goods. By using clean pallets that adhere to these regulations, businesses demonstrate their commitment to compliance and mitigate the potential risks of non-compliant practices. Moreover, complying with these regulations protects businesses from legal consequences and reputational damage.

Preventing Cross-Contamination

Industries that transport different products or materials using the same pallets run the risk of cross-contamination. Clean pallets help minimize the risk of cross-contamination by ensuring there are no traces of previous products, residues, or contaminants on the pallets. This is particularly critical for sectors such as food and pharmaceuticals, where even trace amounts of certain substances can have severe consequences.

Enhanced Efficiency and Cost Savings

Clean pallets contribute to the overall efficiency and cost-effectiveness of supply chain operations. Pallets in good condition, free from dirt, debris, and contaminants, are less likely to cause delays, disruptions, or damage during transportation. Clean pallets reduce the risk of breakage, which can lead to product loss and additional costs. They also minimize the chances of equipment malfunction and conveyor system clogs, resulting in smoother material handling operations and increased productivity. By utilizing clean pallets, businesses can enhance their operational efficiency, reduce downtime, and ultimately save on costs associated with product damage and logistical inefficiencies.

Recognizing the importance of clean pallets, manufacturers like RM2 have implemented measures to guarantee their hygiene. RM2’s BLOCKPal™ composite pallets are engineered from nonporous materials, naturally resistant to bacteria, chemicals, and pests. Additionally, these pallets are non-shedding, eliminating the risk of dust or debris and ensuring a clean and uncontaminated environment for transported goods. RM2 operates three cleaning facilities that adhere to ISO 22000 standards. Their two-step cleaning process includes disinfection, followed by ATP readings of 50 or below to verify the effectiveness of the sanitation. Regular swabbing and RLU readings provide customers with a hygienic audit trail, instilling confidence in the cleanliness of the pallets. The cleanliness of pallets is important for businesses looking to maintain the integrity of their products and implement a smooth supply chain operation. Clean pallets contribute to product safety and quality assurance, and comply with regulatory standards, enhance operational efficiency, and reduce costs. By prioritizing clean pallets, businesses can uphold their commitment to consumer safety, protect their brand reputation, and optimize operational efficiency. RM2, through their smart reusable BLOCKPal™ composite pallets, have revolutionized the industry with embedded autonomous IoT sensor technology to optimize logistics. With nonporous, non-shedding materials, stringent cleaning processes, and hygienic audit trails, RM2 sets an industry standard for clean pallets. Embracing clean pallets is a proactive step toward building a reliable and hygienic supply chain, benefiting businesses and consumers.Conclusion