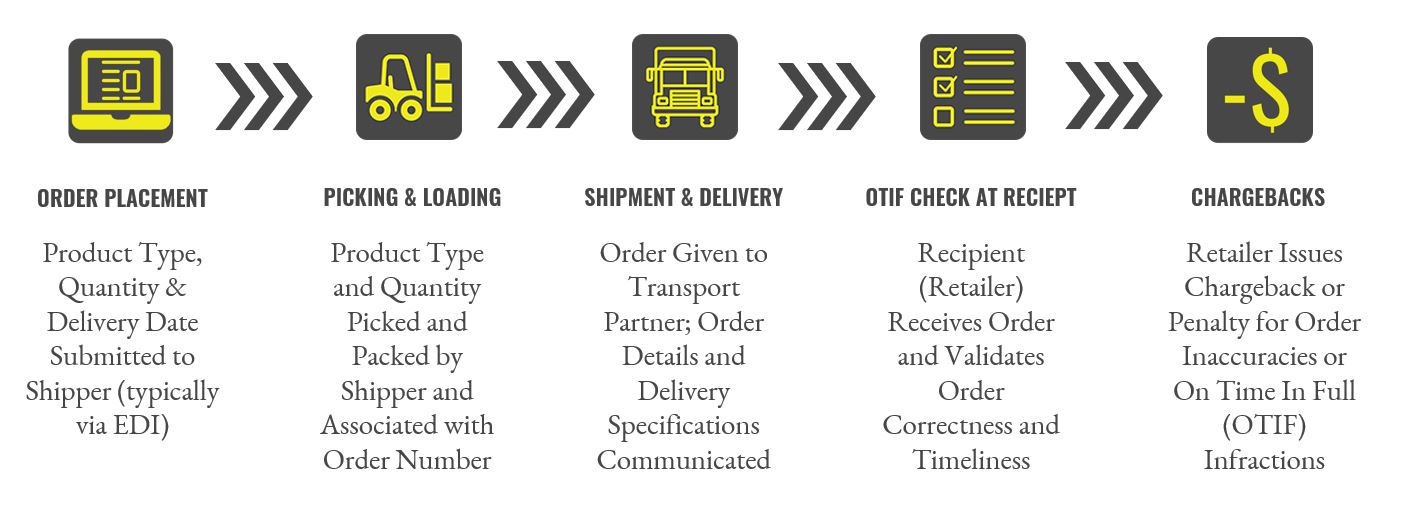

Modern B2B (and B2C) shipments require multiple points of data validation: at order placement, picking and loading, shipment and delivery, and receiving. Product type, order quantity, required delivery date and specifications, pick quantity, pack quantity, order number, batch number, lot number, and serial number are just some of the critical data points communicated up and down supply chains for just a single order. With so much data passing through so many hands, it’s no wonder errors and miscommunications are an increasing – and costly – norm for the industry.

Cause and Effect: the On-Time-In-Full Delivery Metric

On-Time-In-Full (OTIF) is a metric measuring actual manufacturer/shipper shipment quantity and timeliness against retailer/customer expectations, and it’s quickly becoming one of the most important metrics against which suppliers are measured. As consumer expectations have increased exponentially (the “Amazon Effect”), retailers of all formats, not just e-commerce, have been forced to significantly increase delivery speed and decrease out-of-stocks to remain competitive. Incomplete deliveries – even if they’re on time – cause up to 30% of out-of-stocks, which cost retailers an estimated $1 trillion in lost sales each year. With so much at stake, it’s no wonder retailers are enforcing increasingly high service levels with suppliers.For suppliers, the stakes are just as high. In a 2019 survey of 300 retail buyers, 100% of participants said a supplier’s ability to deliver product on time impacted their willingness to work with them, and 73% said they had ended supplier relationships over delivery issues (and this was before COVID-19 sent supply chains into freefall…) Unfortunately for suppliers, increased retailer expectations have sent OTIF non-compliance rates soaring to an average of 20-30%, jeopardizing relationships and ultimately, future sales.

Chargebacks: the High Cost of OTIF Non-Compliance

Although the loss of a retailer’s business is as severe a penalty for OTIF non-compliance as can be suffered by suppliers, it is not the only pain suppliers feel as a result of increased OTIF expectations. Over the past few years, major retailers have enacted significant financial penalties for OTIF non-compliance:

- Kroger fines suppliers $500 for each order that is delivered more than two days late

- Walmart charges suppliers 3% of the purchase price for every order delivered early, late or incomplete

- Target fines suppliers 5% of the cost of goods for shipments late or not complete

At current compliance levels, penalties could total $5-6 billion annually in the US alone. Individually, average-sized suppliers pay over $1.5 million in retailer chargebacks annually, which equates to an average profit margin decrease of a full percentage point. A large CPG can spend up to $11 million annually in OTIF penalties and other costs, solely related to transportation issues.

In current systems, the lack of visibility creates significant opportunities for human error

With so many individuals manually inputting, reading, and responding to so many pieces of critical data, errors occur frequently in all phases of fulfillment, from supplier shipment to shelf replenishment. In a survey of nearly 200 retailers, 62% of cited human error from manual process management as the #1 root cause of inventory fulfillment issues. Things become even more complex when third parties are added to the supply chain, which is the norm: 90% of shippers utilize 3rd party transportation services.

Human error not only causes issues that lead to valid OTIF violations, but lost or incorrect Bills of Lading (BOLs) and other shipping documents, as well as retailer error upon receipt of product can trigger erroneous OTIF violations which are difficult to dispute without a single source of data truth.

Pallet- and Unit-level Data Truth Through New IoT Solutions

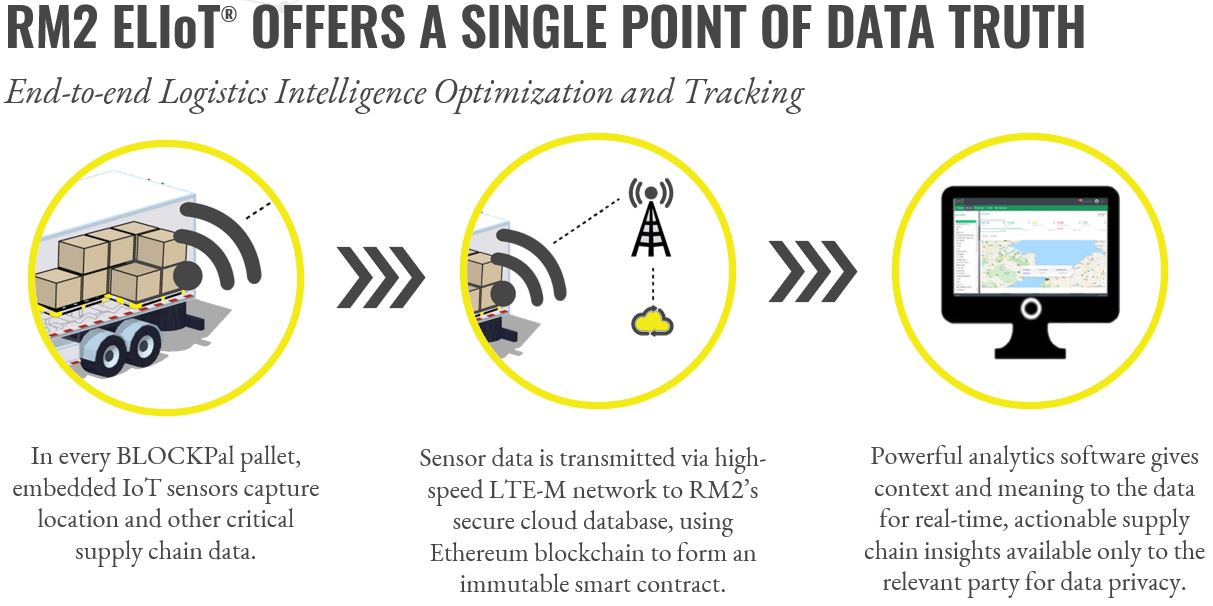

Technology companies, along with pallet and shipping container companies, are developing new ways to accurately capture and securely communicate critical order data to appropriate parties, to help reduce the causes of OTIF infractions, increase transparency, and reduce erroneous OTIF penalties due to human error.

RM2 ELIoT® technology is just such a solution. At the pallet level, RM2 ELIoT is embedded in every BLOCKPal pallet, allowing shippers to associate order data with each pallet load and track location, temperature, and chain of custody from anywhere, at any time.

At the unit or case level, RM2 ELIoT turns “dumb” containers, trays, cases, roll cages, vehicles, racks, and even facilities into smart reporting nodes for the supply chain, enabling them to track and monitor product both indoors and in-transit from a single platform. No gateways, readers, or additional hardware are required, so all authorized parties, from shipper to distribution partner to transportation partner to retailer can securely access the information they need without additional costs, as the data is accessible right from their PC. RM2 ELIoT is interoperable with existing BLE and RFID systems to provide wide area views of products and assets, and seamlessly integrates into existing technology infrastructure via standard API’s.

As consumer expectations for availability and delivery speed continue to increase, so, too, will retailer demands on suppliers. Improving OTIF performance and reducing erroneous OTIF chargebacks will require accurate, real-time, and secure supply chain data management, updated by smart assets interlinked throughout the supply chain. To learn more about how RM2 ELIoT technology makes this a reality, contact us.