There’s an old adage that defines the foundation of business relationships this way:

“Business is built on two things: respect and trust.”

There is a lot of truth in that statement. But in these post-COVID days of ongoing uncertainty and supply chain fragility, we’d like to amend it thus:

“Business is built on three things: respect, trust and real-time visibility.”

Why the change? Because now more than ever businesses reliant upon free-moving, secure supply chains need real-time visibility to survive, let alone succeed. We’d like to point to some recent red flags. If your business has a physical supply chain, you know theft is a significant issue. Thieves are growing ever more sophisticated and emboldened, lurking around distribution centers, tracking loads, following truck drivers until they stop, and even breaking into enterprise systems to understand what’s going where. It’s how they plan their heists.

And while the world was on lockdown these past 15 months, one would think the thieves would take a break. That’s not the case. According to data from CargoNet, third-quarter 2020 thefts increased each month year-over-year. In September 2020 alone, the increase in thefts surged 26.92% year-over-year. CargoNet said the average theft in 2020 was valued at $166,334, up 19% from the previous year.

Here’s what’s interesting about this COVID crime spree. Instead of targeting electronics and other high-ticket consumer items, thieves went after products like pharmaceuticals, food and beverages. The reason? They steal what they can sell quickly. In an economic downturn, people spend money on food and beverages. Some will also spend on illicit pharmaceuticals. A plus for crook is that evidence of this type of thievery is quickly consumed.

Red flag number two: instead of stealing entire tractor loads, thieves have demonstrated a preference for pilferage. The increase is due to the ease of pulling off a theft coupled with the loss of merchandise often going unnoticed until the truck arrives at its destination and the discrepancy is noted. Back to the CargoNet report, trailer break-ins and pilferages are on the rise and accounted for 22% of all reported thefts in the third quarter of 2020.

Red flag number three: the rise in fictitious drivers. CargoNet reported a huge spike—163%—in this crime during the pandemic and place part of the blame rests on mask-wearing. This helped fictitious drivers hide their faces from security cameras and simply drive off with the goods. All sorts of other COVID-enabled chaos protected these sneaky drivers from detection and no one was the wiser until the load was long gone.

Real-time visibility is no longer a nice thing to have. It’s a must-have.

Trucking companies are fighting back with low tech and some high-tech solutions. Low tech comes in the form of driver training like where to park during layovers, starting trips fully rested and fed to avoid stops in the first 200 miles, and avoiding “hot spots” for thieves. Other lower-tech solutions are better locking devices on trailers. Obviously, this is not enough to stop today’s criminals, who are increasingly sophisticated in their methods.

Trucking companies Averitt and C.R. England are using asset-based tracking such as GPS to see the location of their trucks and trailers, be alerted if there’s a deviation in the designated route, and increase recovery rates of stolen trailers.

While it’s an important start to protecting loads, deterring theft, and maintaining customer relationships, there are smarter, higher-tech options that are easily integrated into a business that provide real-time visibility in a far more granular, actionable way.

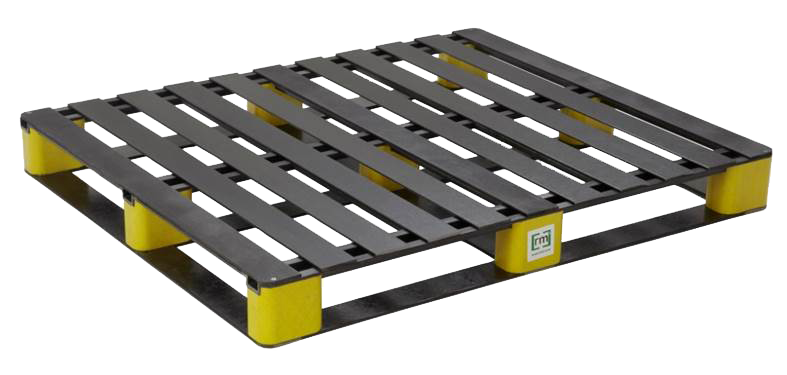

Leading the pack of sophisticated asset monitoring systems is RM2’s sensor-based, cloud-enabled reusable BLOCKPal™ composite pallets with RM2 ELIoT®—short for end-to-end logistics intelligence optimization and tracking—Internet of Things technology for pallet traceability, supply chain visibility, and real-time actionable insights—the enablers needed to thwart thievery, elevate data availability and accuracy for day-to-day operations, and protect business relationships.

A very clever solution that is literally plug-and-play

RM2 created the RM2 ELIoT technology to make supply chain visibility at the pallet level easy to implement on the ground—the manufacturing floor or distribution center dock for example—and simple to integrate with the back-office enterprise systems. The goal being regardless of what ERP, e-commerce platform, inventory management system, or warehouse management system (a company was using, RM2 ELIoT would easily “sit on top” of the existing system and work alongside.

Simply put, RM2 ELIoT works off unique identifiers like barcodes and QR codes on shipping labels and associates with a specific sensor-enabled pallet or other units such as a caseload down to individual products.

Visibility on a company’s systems begins when that barcode or QR code is scanned, something that can be done with a mobile app. Thus, as pallets or other units are scanned and loaded into a trailer or container, customers have an accurate “living” record of what’s in the load that can be tracked in real-time from that moment forward.

In addition to tracking, the sensors also monitor and detect changes in temperature, vibration, and acceleration. This captures the location, condition, and movement of products and assets in real-time. In the event of a deviation outside the norm—the truck stops, the trailer is opened, pallets and/or items are removed/pilfered, the temperature changes—an alert is sent so the company can respond to whatever unplanned activity is underway.

All of this is enabled via the cloud and the LTE-M network, which makes the location and condition of the pallet or item visible both indoors and in transit without requiring the user company any outlay of capital or time for hardware or IT development. Additionally, the company has access to RM2’s secure could database, analytics and reporting software. All of this is accessible via a secure web portal.

Back to thieves and the day-to-day necessities of matching ship quantity to invoices

This new cloud-enabled, real-time visibility coupled with actionable alerts makes for a robust counter-measure to supply chain crime. Remember how fax machines changed our lives in the early 1980s? How smart phones changed our lives in the 2010s? Well, pallets, cases, and individual items embedded with cloud-enable sensors are that level of transformation. Hopefully, the immediacy of detection will bring down the increase in thefts.

However, most supply chain visibility and tracking issues center on the day-to-day tasks of matching ship quantities to invoices, validating shipment data, and shipment data accuracy; tasks critical to maintaining harmony with all business. RM2 ELIoT technology excels here, too. Whether we’re talking about B2B, manufacturer to retailer, or B2C, RM2 ELIoT’s cloud-enabled digital trail, accessible from your desktop or smartphone, can help resolve conflicts caused by discrepancies in what the shipper knows they shipped and what the receiver says they got.

This is a much more expensive issue than theft as it happens all the time. And when companies have hard data from the moment a pallet or product is shipped until it’s delivered and every step along the chain, the proof is in the pudding so to speak.

Today, nearly all shipments rely on some sort of human interaction to document or track supply chain transaction data and many shipments are literally “in the dark” once they begin their journey from point A to point B. This leaves the door open to theft, human error or both, along with a loss of respect and trust between supplier and customer. RM2 ELIoT technology changes that. Let the transformation—and business relationship preservation— begin.

In addition to always knowing a pallet’s whereabouts within the supply chain, RM2 BLOCKPal™ pallet users also receive real-time alerts on shipment status that may indicate out-of-the-ordinary handling or changes in temperature. The last is extremely critical for everything from fresh meats and seafood, fresh produce, cut flowers, and pharmaceuticals—any product sensitive to temperature changes.

This visibility does not require scanners, other external devices or investment. RM2 ELIoT pallets speak directly to the Cloud. Access to data and analytics is via RM2’s Cloud Systems and can be easily integrated into a customer’s IT infrastructure via standard APIs.

Another big difference between IoT-enabled pallets from RM2 and RFID and is loss results. RM2 ELIoT pallets have proven to reduce loss of the pallets themselves to less than half a percent versus 2-3% and higher for tech-enabled wood and plastic pallets.

Lastly, IoT-enabled pallets like BLOCKPal are smart in their own right but ultimately become more powerful when part of an interconnected ecosystem of supply chain events.

Where the Rubber Meets the Road

Overall performance, specific use case, and ease of implementation are critical factors when choosing tech-enabled pallets. As with everything else, cost is another factor. There are several things to consider in terms of cost: pallets, technology, infrastructure, and cost over the life of the solution.

One final lesson from the global pandemic is that we all need to expect the unexpected and plan for it. For those who are responsible for supply chains, now is the time to mitigate the risk of business-altering disruptions and as this post explains, supply chain visibility is a powerful solution. The best options provide not only visibility but also actionable, real-time alerts and ongoing data that puts control back into your hands regardless of what life, nature, or man throws at you.

RM2 invites you to connect to discuss your specific needs and how our RM2 ELIoT can deliver the exact solution you’re looking for. Start the conversation here.